Plastic used in food packaging accounts for a significant proportion of plastic waste in landfills. In the face of growing environmental concerns, researchers are turning to biosimilars.

Developed by scientists from the Chinese University of Hong Kong (CUHK) Edible, transparent and biodegradable material With great potential for food packaging. Their work has been published in Journal of Food and Agricultural Sciences.

The over-reliance on petrochemicals and the non-biodegradability of plastic packaging makes it a major contributor to environmental pollution. The CUHK team focused their research on bacterial cellulose (BC), an organic compound derived from specific bacteria, recognized as a sustainable, accessible, and non-toxic solution to replace the ubiquitous use of plastic.

Professor To Ngai of the Department of Chemistry at CUHK, who authored the study, explained that BC’s remarkable tensile strength and versatility are key to its potential.

He said:Much research has been done on BC, including its use in smart packaging, smart films, and functional materials created by blending, coating, and other technologies. These studies demonstrate the potential of BC as an alternative to single-use plastic packaging materials, making them a logical starting point for our research.. “

Unlike the cellulose found in plant cell walls, BC can be produced by microbial fermentation, eliminating the need to harvest trees or crops. To Ngai noted that because of this, “… This production method does not contribute to deforestation or habitat loss, making BC a more sustainable and environmentally friendly material as an alternative to plant cellulose. “

To date, widespread adoption of BC has been limited by its unfavorable sensitivity to air moisture (hygroscopicity), which negatively affects its physical properties.

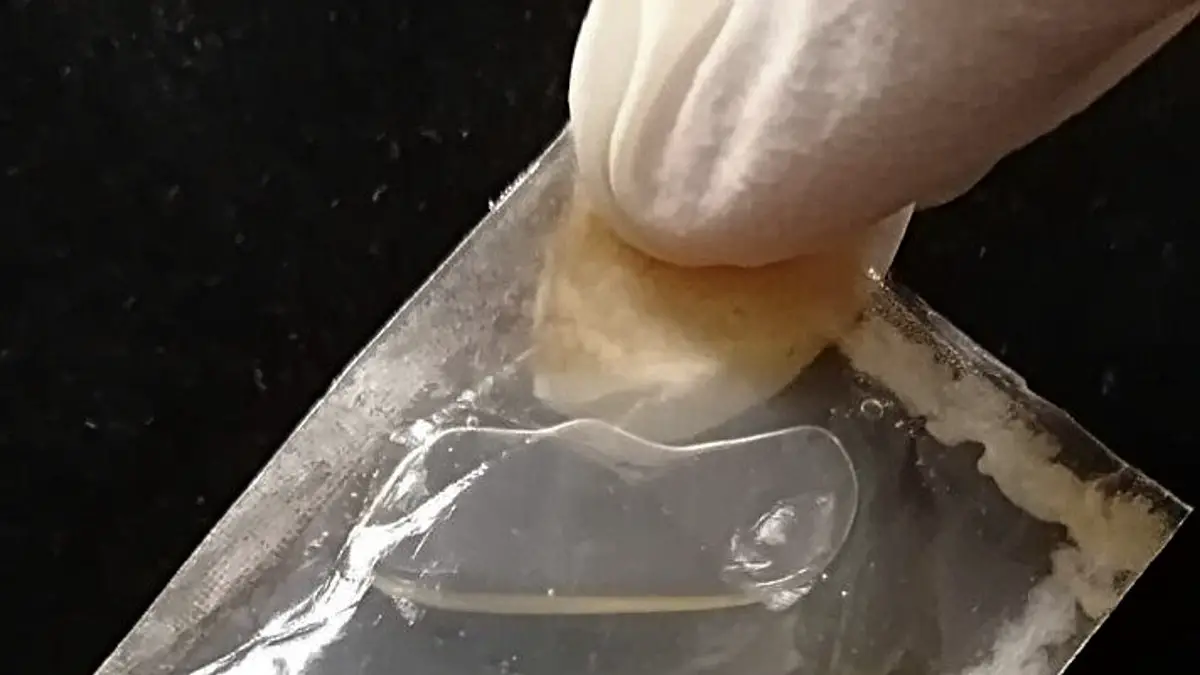

In the paper, the researchers present a new approach to overcome the limitations of BC-based materials. By incorporating some soy protein into the structure and covering it with an oil-resistant compound, they were able to create an edible, transparent, and robust BC-based composite packaging.

To Ngai explained that this approach has great scaling feasibility: “It does not require specific reaction conditions such as chemical reactions, but rather a simple and convenient way of mixing and coating. This approach offers a promising solution to the challenge of developing sustainable and environmentally friendly packaging materials that can replace single-use plastics on a large scale.. “

The study showed that the alternative to plastic can completely biodegrade within one to two months. Unlike other bio-derived plastics such as polylactic acid, BC-based composites do not require specific industrial composting conditions for decomposition.

“The materials developed in this research are completely edible, making them safe for turtles and other marine animals to consume without causing aquatic toxicity in the ocean.. Professor Ngai explained.

Researchers CUHK They are now exploring directions for future research. They hope to improve the versatility of the modified BC films, making them suitable for a variety of applications. Specifically, they are focused on developing a thermoplastic that can create strong bonds between cellulose and bacteria, allowing it to be easily molded into various shapes when heated.

“One of the main challenges with bacterial cellulose films is that they are not thermoplastics, which limits their potential for use in certain applications. By addressing this problem, we hope to make bacterial cellulose films more competitive with traditional plastics while remaining environmentally friendly.Professor Ngai explained.

Professor Ngai hopes the current study will help combat the overuse of single-use plastics, which can last for hundreds of years after a few days on supermarket shelves.

“This research is a reminder that natural raw materials may actually possess the properties needed to outperform the functionality of plastic packaging.He finished.

artificial

Despite the challenges inherent in BC’s moisture sensitivity, the CUHK research team has succeeded in developing a viable, environmentally friendly alternative to single-use plastic packaging. Through a combination of soy protein and an oil-resistant compound, a biodegradable, transparent, and edible material with promising potential for food packaging was created. Efforts are still needed to improve its versatility and overcome the challenge of non-thermoplastics.

For a better understanding

What is bacterial cellulose? BC is an organic compound produced by certain bacteria. It is considered a sustainable, accessible and non-toxic alternative to plastic.

Why is BC an environmentally friendly choice? BC is produced by microbial fermentation, eliminating the need to cut down trees or harvest crops. So it does not contribute to deforestation or habitat loss.

What are the challenges in using BC? BC is sensitive to moisture in the air, which may affect its physical properties. Additionally, they are not thermoplastics, which limits their use to certain applications.

How did the research team overcome these challenges? The researchers incorporated soy protein into BC and coated it with an oil-fighting complex. This made it possible to create an edible, transparent and strong substance.

How long does this substance take to decompose? The study showed that the alternative to plastic can completely biodegrade within one to two months.

What is the effect of this substance on marine life? The developed material is edible and does not cause water toxicity in the ocean.

Information: Ka Man Cheung et al, Edible, robust, low-moisture bacterial cellulose derived from biosynthesis and physical modification of food packaging, Journal of Food and Agricultural Sciences (2023). DOI: 10.1002/jsfa.12758

Key annotation: By incorporating soy protein into the structure and covering it with an oil-resistant compound, the CUHK team succeeded in creating transparent, strong, edible composite packaging made from BC. Credit: to Ngai

[ Rédaction ]

“Music guru. Incurable web practitioner. Thinker. Lifelong zombie junkie. Tv buff. Typical organizer. Evil beer scholar.”

More Stories

Immunology, the science that changes your health

In collaboration with USTHB and ETUSA: a flag for all convoys across Algiers Province

The effectiveness of low-carb diets has been confirmed