Photo by Hugo Sebastien Huppert, Press

Mathieu Desjardins, category manager for protective equipment, is collecting data. The technology has been offered for two seasons to professional players, and since last season to sporting goods retailers.

Photo by Hugo Sebastien Huppert, Press

Nick Suzuki notes the results of the scan.

Photo by Hugo Sebastien Huppert, Press

In a 3D printer, thin layers of plastic powder are deposited one by one. The laser melts it according to the pattern obtained by digitizing. Twenty hours are needed to produce a batch of 20 custom helmet inserts. At the end of this process, a thick “cake” is extracted from the printer.

Photo by Hugo Sebastien Huppert, Press

We release pieces of stuffing from the “cake”. The remaining powder can be reused.

Photo by Hugo Sebastien Huppert, Press

The upholstery pieces are then sanded and stained, then veneered. The first players to test this personalization technique were Cal Makar and Jack Eichel. In the Habs he has recently benefited from Paul Byron, Cole Cofield and Nick Suzuki.

Photo by Hugo Sebastien Huppert, Press

At its innovation center in Blainville, Bauer maintains pieces of equipment from previous generations. R&D engineers can study older models that are between 15 and 20 years old. Within moments, Nick Suzuki found the skates he had been wearing for his pickup hockey game.

Photo by Hugo Sebastien Huppert, Press

Parts that fail stress tests are also preserved. For example, this pair of shoulder pads that split after 96 hours of testing.

Photo by Hugo Sebastien Huppert, Press

Visiting a ski boot manufacturing area where about fifty people work

Photo by Hugo Sebastien Huppert, Press

The vast majority of Power Skates are made in Asia. However, the Blainville plant produces about 20,000 pairs per year. These are mainly for professional gamers.

Photo by Hugo Sebastien Huppert, Press

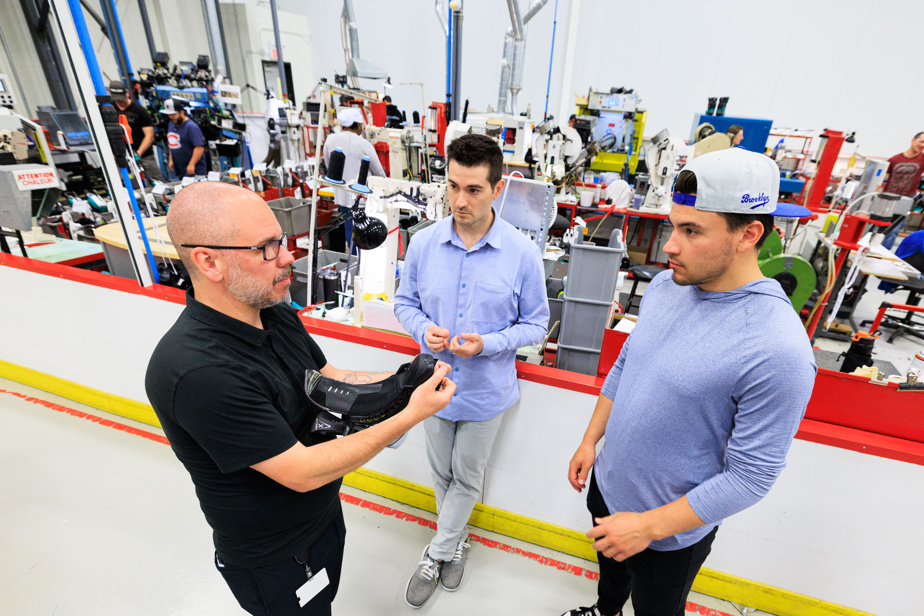

Nick Suzuki speaks with Patrick Garry, production manager (in black), and Justin Bonitatipos, a representative with a few NHL teams, including the Canadiens. Nick Suzuki takes advantage of his visit to point out that the sole of his skates was way too narrow last season compared to the boots.

Photo by Hugo Sebastien Huppert, Press

Marc-Andre Dickey, lab technician, showing wand customization hardware. “I rarely change anything in my hardware,” Nick Suzuki later explained. I have tried different sticks over the years but i always go back to the same ones i already had on the juniors. Henry Breslin, director of Athlete Services (not pictured), points out that players can tell in seconds if a stick is a few grams overweight.

Photo by Hugo Sebastien Huppert, Press

Last stop: the impact test room. A discus thrower throws a disc at a speed of more than 130 km / h on a skate (our photo). “I get some like that,” the Canadian quarterback sneers. A little later, there is another device that simulates side impacts on a helmet. Although no equipment manufacturer can assure athletes that a helmet will protect them 100% from concussion, the entire internal structure of the helmet is designed to absorb as much energy as possible.

“Hipster-friendly tv trailblazer. Problem solver. Infuriatingly humble introvert. Reader. Student. Subtly charming bacon maven.”