Industrial water chillers are used in a variety of applications where chilled or liquid water is circulated through process equipment. How it works ? Find this article.

coolant operation

Although there are a variety of combinations ice water, Most of them use the same principle to evacuate heat. An essential part of the process is the coolant or coolant. This retains more heat than water and helps maintain the process cooling effective. Heat is removed from the liquid cooling and launched into the air.

The concept of coolant is based on the principle that cooling involves removing the heat of the process and released into the air. Liquid glycol is the heat transfer carrier from the process to the cooling system. Convection eliminators consist of the following components:

- capacitor

- compressor

- Organizer

- vaporizer

The refrigerant process is designed to change the refrigerant from liquid to vapor and back to liquid. The refrigerant, in its vapor form, removes heat from the process. When returned to its liquid form by the compressor and condenser, it recycles through the system to capture heat from a process or process. This is the cooling cycle.

Use of refrigerant

Chillers use water as a coolant to cool a building or part of a building. Although refrigerated air conditioning systems are perhaps the most widely used in commercial operations that require large capacity cooling – Such as supermarkets or industrial facilities.

Lower system costs coupled with environmental benefits mean more people are choosing industrial refrigeration installations.

Application of chilled water systems at home

In warmer climates, refrigerant can be used instead of standard air conditioning to achieve and maintain internal temperatures more comfortable. The pipe The refrigerant connects to the cooling devices in the air handling system.

The air there is cooled by the chilled water for banners, Then distributed throughout the building via a series of pipe lines. This creates an environmentally friendly solution for home cooling. Since chilled water systems are great for cooling many separate individual areas, they are also an ideal way to maintain temperatures in tall buildings and hotels.

After the water cools the air, it returns to the coolant at about 13°C. proces cooling It starts again, either on a timer or at the request of an individual.

Low benefit effect

The water used in this cooling systems It can be stored in a cooling tower, although some big cities are used chilled water It has been provided by utilities since the mid-1960s, eliminating the need for storage space.

Alternatively, the water can be cooled overnight, allowing homeowners and businesses to benefit from it Electricity tariff off peak. This water is usually stored in a tank for use the next day.

coolant maintenance

Although the basic mechanism of the coolant is the same for all types, as with any type industrial equipmentRegular maintenance ensures that it will perform to its specifications. Manufacturers strongly encourage scheduled monitoring and inspection of coolant components and provide instructions on how to do this.

The heat exchange process is an important part of the operation of the coolant. The condenser coils may be clogged or have an open air passage. The ability of the refrigerant to function properly depends largely on the refrigerant. An improperly charged coolant can seriously affect the performance of the coolant.

The water used in the cooling towers must comply with the standards of good water flow. Debris, dirt, solids, and contaminants can interfere with water flow The radiator is damaged.

To get the best performance out of the coolant, all of its tanks should be checked to ensure they have an adequate supply of liquids. Refrigerants operate at their best at 50°F (10°C). Uncontrolled changes in temperature can adversely affect the operation of the coolant.

For best results, regular review of inlet and outlet glycol temperatures helps spot potential problems. all equipment Collect dirt and dust during the manufacturing process. For maximum effectiveness, the parts from a . are shown cooler It should be cleaned regularly. Filters must be changed to prevent clogging.

Although there are a variety of coolants, most of them work on the same principle as heat removal. As with any type of industrial equipment, regular maintenance is essential to the operation of the coolant. Chilled water unit is a device that is part of refrigeration units. Appointment over here To learn more about cold production and its equipment.

“Hardcore beer fanatic. Falls down a lot. Professional coffee fan. Music ninja.”

More Stories

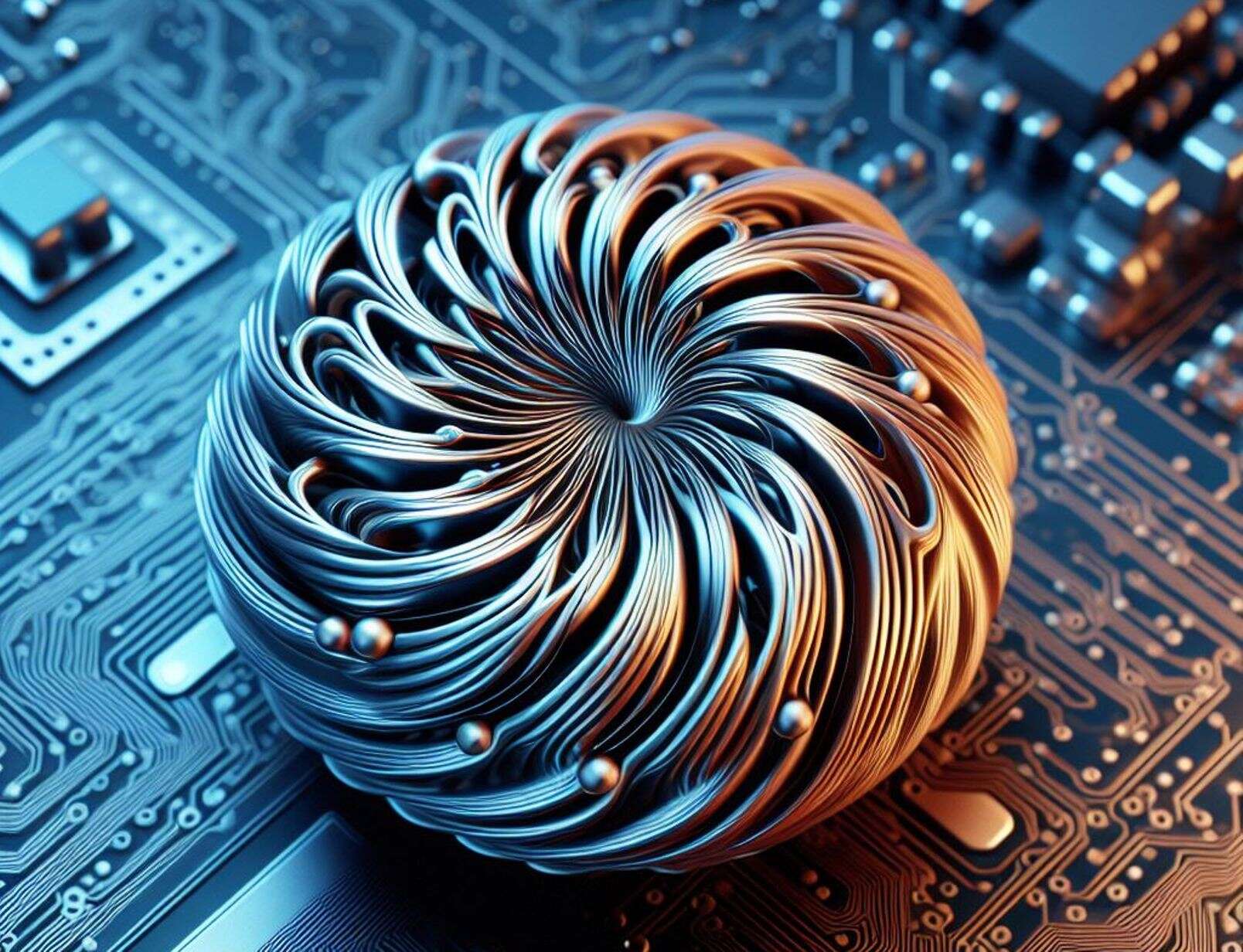

Skyrmions, increasingly promising magnetic particles for future computers

A very simple tip for better brainstorming

How to install Windows 11 on an incompatible PC, and fix your Galaxy with green line for free, here's the summary