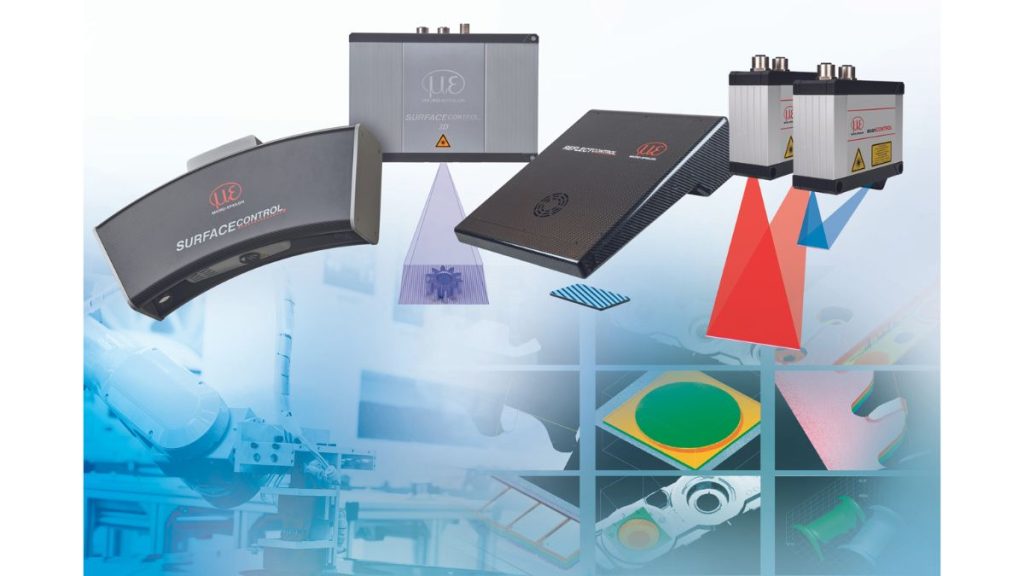

With new generations of SurfaceControl, reflectControl and scanControl, Micro-Epsilon offers a range of powerful 3D products for precise control of geometry, shape and surface. The powerful 3DIInspect software, compatible with all Micro-Epsilon 3D sensors and equipped with many features, is a major asset.

Micro-Epsilon offers 3DIInspect software for all 3D sensors in its portfolio. This is easy to use and can be operated intuitively. The program makes it possible to configure the sensors, but also to record measurement data. The diverse set of tools extends from point cloud alignment to programs for calculating distance, height, angle and radius, as well as a simple output option to the API and further processing of measurement data. In addition to the standard version, the functional extension “Automation” of automated production processes is presented.

Micro-Epsilon’s comprehensive 3D software package is compatible, among other things, with SurfaceControl 3D sensors. They are used for rapid 3D measurement and inspection of diffuse reflective surfaces such as metal, plastic or ceramic. With a z-reproducibility of up to 0.4 µm, the sensor sets new standards in high-precision 3D measurement technology. The reflection sensor is designed for 3D measurements on reflective and glossy surfaces. The sensor can be used statically for measurements with micrometer accuracy for production line monitoring or for embedded checking, for example on a robot. The scratch pattern generated on the sensor screen is reflected on the surface of the object to be measured in the sensor cameras. Surface aberrations result in distortions at the edges of the light which are then evaluated by the software.

The scanControl series scanners are some of the most powerful sensors in the world in terms of accuracy and frequency measurement. To create 3D scans, movement is required. Scanners are moved over the object to be measured, for example by a robot or a moving device, or by conveyor belts that make the objects to be measured after the scanner. Micro-Epsilon laser scanners offer a unique combination of high dynamics, precision and compact size. Several measuring ranges are available as well as red and blue laser technologies and many accessories. The scanners are compelling for both integration and serial use on the production line.

“Hardcore beer fanatic. Falls down a lot. Professional coffee fan. Music ninja.”

More Stories

We tell you everything!

Yeast can help preserve food

Communications Assistant – MaCommunaute.ca