Last Friday, French astronaut Thomas Pescet flew for the second time to the International Space Station (ISS) for a 6-month flight. In doing so, he becomes the first French captain of the International Space Station. And if we’re talking about that today, it’s because it’s shipped with 3D printed parts, in particular packaging for Meals provided by the Hanaf group, as well as a protective bag for the French astronaut sleeping squad. These parts are designed from Recyclable and edible foam, Based on PHA, is a polymer of natural origin made by bacteria. These foams, designed with the ComposiTIC technology platform, provide high protection, isolating shock and vibration.

The ComposiTIC technology platform was established in 2014 at the University of South Brittany (UBS). Its goal is to develop Vehicles Innovative thanks to robotic fiber placement technology. The platform was ordered by CNES as part of Thomas Pesquet’s ESA Alpha mission. Over the next six months, the French engineer must do several maintenance as well as a hundred scientific experiments aboard the International Space Station. Additive manufacturing has been called for.

These are PHA pellets that have been transformed into filament for 3D part printing (Image credits: UBS)

3D printed foam to protect scientific equipment

Conducting scientific experiments in space creates different limitations than those on Earth, particularly with regard to packing: Any test onboard the International Space Station must be carefully stored in some kind of box made of foam to protect against vibrations. The goal is to ensure that the equipment is functional and reliable once it reaches the International Space Station. As part of the Alpha mission, one of the requests formulated by the French astronaut was to replace traditional materials from the oil industry with recyclable foam, which would take less space and above all generate less waste.

One of Thomas Pesquet’s experiments concerns sleep in space: The astronaut will wear a headband designed by startup Dreem, which will allow analysis of the duration and quality of his sleep. Yves Marie Curie is the Technical Director of the ComposiTIC technology platform. He explains:We were contacted as part of the ‘Renewable Foam’ experiment to design a 3D-printed recyclable foam that will be used to protect Thomas Pesquet’s sleep study headband. This packaging aims to isolate the device from shock and vibration.. ”

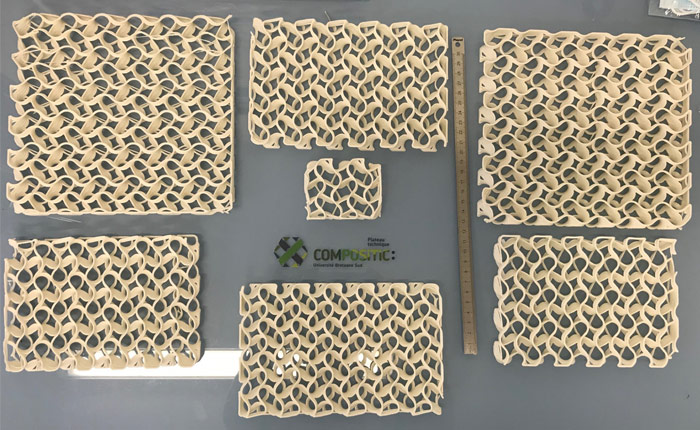

Multiple panels were 3D printed (Image credits: ComposiTIC)

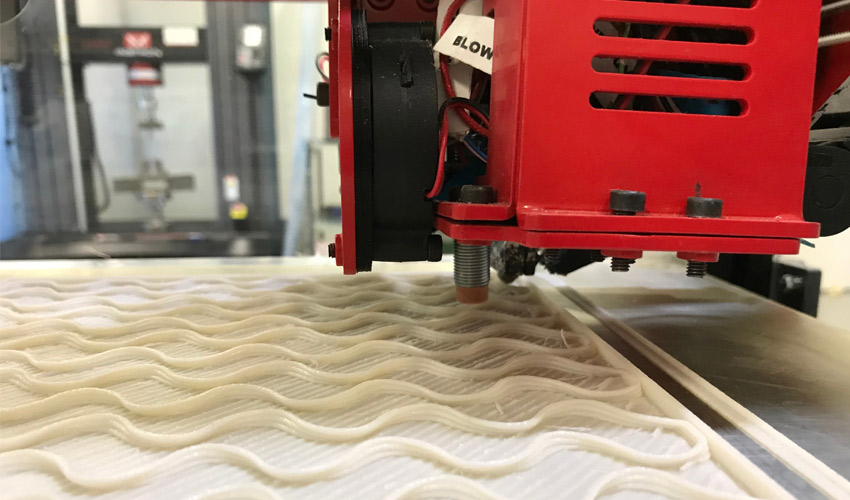

So the 3D Tech Platform printed a recyclable foam bumper box made of PHA. thanks for the Design methods for additive manufacturing (DfAM), the team was able to visualize the honeycomb structure in order to improve the weight and resistance of the part. What is interesting is the choice of materials. Yves Marie Curie actually identifies:Even if it is still plastic, this time it is no longer made from materials derived from petroleum but made by living organisms: bacteria, giving these bioplastics the ability to degrade very quickly in the environment.About twenty panels could be 3D printed in order to create 4 boxes to protect not only the headband but also the rest of the science material during the flight. These parts will then be used on deck to grow vegetables: the material will be able to decompose and provide the plant with all the nutrients needed for its growth.

The second element designed by 3D printing is also part of the protection, but this time it’s about food. Baptized Edible foam, Package consist of 3d printed walls with edible foam; So astronauts could eat these walls. Note, however, that as part of the Alpha mission, only the storage function has been preserved, and the foam will not be consumed. However, we imagine the edible character might be of use for future missions.

We are eagerly awaiting the results of the various experiments that the team conducted on board the International Space Station! What do you think about the use of additive manufacturing in space? Feel free to share your opinion in the article comments or with members 3D forum. Find all of our videos on our channel Youtube Or follow us The social networking site Facebook or Twitter !

“Hardcore beer fanatic. Falls down a lot. Professional coffee fan. Music ninja.”

More Stories

We tell you everything!

Yeast can help preserve food

Communications Assistant – MaCommunaute.ca